The automotive industry has witnessed remarkable advancements in wheel technology, with aluminum alloy wheels emerging as a superior choice for enhancing vehicle durability and performance. These lightweight yet robust components have revolutionized how vehicles handle stress, weight distribution, and overall longevity. Modern drivers increasingly recognize that the choice of wheels significantly impacts not only aesthetic appeal but also fundamental vehicle characteristics including fuel efficiency, handling precision, and structural integrity. Understanding the mechanisms through which these advanced wheel systems contribute to vehicle durability provides valuable insights for automotive enthusiasts, fleet managers, and industry professionals seeking optimal performance solutions.

The foundation of aluminum alloy wheels lies in their sophisticated metallurgical composition, which combines aluminum with carefully selected alloying elements such as magnesium, silicon, and copper. This precise blend creates a material matrix that delivers exceptional strength-to-weight ratios while maintaining superior corrosion resistance. The crystalline structure of these alloys provides enhanced fatigue resistance, enabling wheels to withstand millions of stress cycles without compromising structural integrity. Manufacturing processes including heat treatment and controlled cooling optimize the grain structure, resulting in wheels that demonstrate remarkable durability under diverse operating conditions.

Engineers have developed multiple alloy grades specifically tailored for different automotive applications, from high-performance sports cars to heavy-duty commercial vehicles. Each formulation addresses specific durability requirements while maintaining the fundamental advantages of reduced weight and improved heat dissipation. The molecular bonding characteristics of these specialized alloys create resistance to crack propagation, significantly extending wheel lifespan compared to traditional materials. Quality control measures during production ensure consistent material properties throughout each wheel, eliminating weak points that could compromise long-term durability.

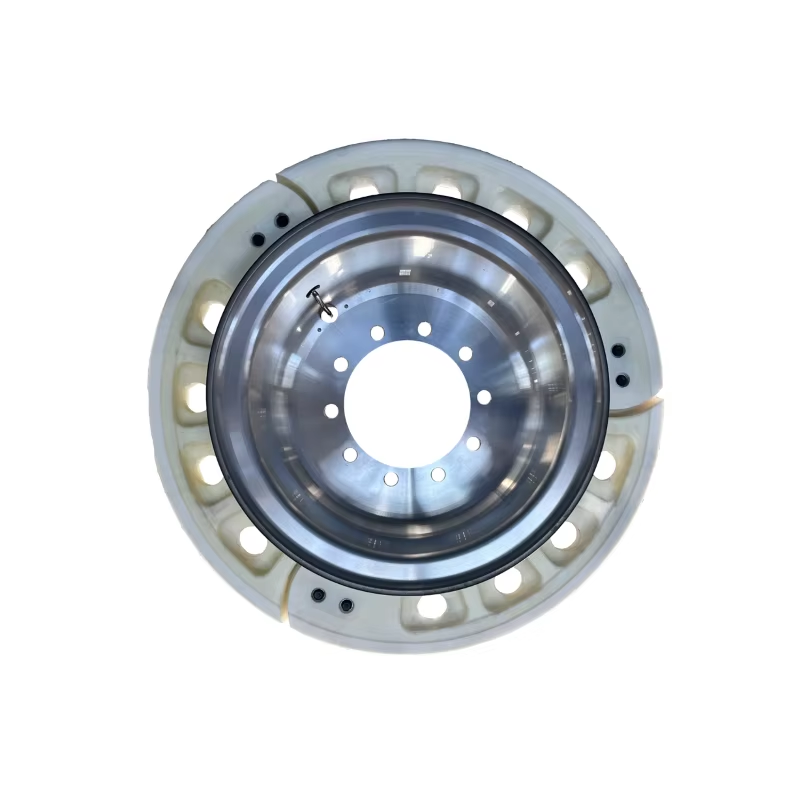

The geometric design of aluminum alloy wheels incorporates sophisticated engineering principles that optimize stress distribution across the entire wheel structure. Spoke patterns, rim profiles, and hub configurations work synergistically to channel forces from road impacts, braking loads, and cornering stresses through predetermined pathways. This engineered approach prevents stress concentration points that typically lead to premature failure in conventional wheel designs. Computer-aided analysis and finite element modeling guide the development of wheel geometries that maximize durability while minimizing weight penalties.

Load transfer characteristics of aluminum alloy wheels demonstrate superior performance under dynamic conditions, effectively managing the complex forces generated during acceleration, braking, and directional changes. The inherent flexibility of aluminum alloys allows controlled deformation under extreme loads, absorbing energy that would otherwise damage vehicle suspension components or chassis structures. This energy absorption capability contributes significantly to overall vehicle durability by protecting interconnected systems from excessive stress transmission.

Thermal management represents a critical factor in wheel durability, particularly under demanding operating conditions such as heavy braking or high-speed driving scenarios. Aluminum alloy wheels excel in heat dissipation due to their superior thermal conductivity properties, effectively channeling heat away from brake components and tire contact patches. The increased surface area provided by spoke designs and ventilation channels creates multiple pathways for convective cooling, maintaining optimal operating temperatures even during sustained high-performance use.

Temperature regulation through efficient heat transfer prevents thermal cycling damage that commonly affects wheel materials over time. Aluminum's natural ability to conduct and radiate heat helps maintain consistent material properties, preventing the thermal stress that can lead to fatigue cracking or dimensional changes. This thermal stability directly contributes to extended wheel life and maintained performance characteristics throughout the service interval. Advanced manufacturing techniques create internal cooling passages and optimized surface textures that further enhance heat management capabilities.

The relationship between wheel thermal performance and brake system durability creates significant advantages for overall vehicle longevity. Improved heat dissipation from aluminum alloy wheels reduces brake component temperatures, extending the service life of pads, rotors, and brake fluid systems. Lower operating temperatures minimize brake fade phenomena, maintaining consistent stopping performance and reducing wear rates across the entire braking system. This thermal management contributes to reduced maintenance requirements and extended component replacement intervals.

Heat-related expansion and contraction cycles in wheel-mounted brake components benefit from the stable thermal environment created by efficient aluminum alloy heat transfer. Reduced thermal stress on brake calipers, mounting hardware, and rotor attachment points prevents loosening, warping, and premature wear. The cumulative effect of improved thermal management extends beyond individual components to enhance the durability and reliability of the entire vehicle braking system.

The reduction in unsprung weight achieved through aluminum alloy wheels creates cascading benefits throughout the vehicle's mechanical systems, significantly enhancing overall durability and performance. Lower wheel weight reduces the inertial forces transmitted to suspension components during road surface irregularities, decreasing stress on shock absorbers, springs, and mounting points. This reduction in dynamic loading extends component life while improving ride quality and handling precision. The mathematical relationship between unsprung weight and suspension performance demonstrates measurable improvements in fatigue resistance across multiple interconnected systems.

Steering system components experience reduced loads due to decreased wheel inertia, particularly during directional changes and over road surface variations. Power steering systems operate more efficiently with reduced wheel weight, experiencing less stress on pumps, hoses, and steering gear assemblies. The reduced effort required for wheel movement translates into extended component life and improved system reliability. Electronic stability control and anti-lock braking systems also benefit from more predictable wheel dynamics, enhancing their effectiveness while reducing system stress.

The weight reduction provided by aluminum alloy wheels creates measurable improvements in drivetrain efficiency and component longevity. Reduced rotational mass requires less energy for acceleration and deceleration cycles, decreasing stress on engine, transmission, and driveline components. This efficiency improvement translates into reduced wear rates for clutches, torque converters, and differential assemblies. The cumulative effect of improved efficiency extends component service intervals while enhancing overall vehicle reliability.

Fuel system benefits emerge from reduced engine load requirements, leading to more efficient combustion cycles and reduced component wear. Engine mounts, transmission mounts, and driveline supports experience lower dynamic loads due to reduced acceleration forces required for wheel motion. These improvements contribute to extended engine life, reduced maintenance requirements, and improved overall vehicle durability throughout its service life.

Modern aluminum alloy wheels incorporate advanced protective coating systems that provide exceptional resistance to environmental corrosion and chemical attack. Multi-layer coating processes including primer applications, color coats, and clear protective finishes create barrier systems that prevent moisture, road salt, and atmospheric contaminants from reaching the base aluminum material. These protective systems undergo rigorous testing to ensure performance under extreme environmental conditions including coastal salt exposure, industrial pollution, and severe weather cycles.

Electrochemical protection mechanisms inherent in aluminum oxide formation create self-healing properties that maintain corrosion resistance even when surface coatings experience minor damage. The natural passivation layer that forms on aluminum surfaces provides ongoing protection against oxidation and chemical attack. Quality control processes ensure coating adhesion and thickness consistency, providing long-term protection that extends wheel service life significantly beyond conventional materials.

The chemical resistance characteristics of aluminum alloy wheels provide superior durability when exposed to road chemicals, cleaning agents, and industrial environments. Resistance to chloride attack from road salt applications prevents the pitting and crevice corrosion that commonly affects other wheel materials. The stability of aluminum alloys under pH variations encountered in typical automotive environments ensures consistent performance without degradation of mechanical properties.

Cleaning and maintenance procedures for aluminum alloy wheels utilize their inherent chemical resistance to maintain appearance and performance throughout their service life. The compatibility with automotive cleaning products and protective treatments allows for effective maintenance without material damage or property degradation. This chemical stability contributes to extended appearance retention and structural integrity over time.

Contemporary aluminum alloy wheels benefit from sophisticated manufacturing processes that ensure consistent quality and optimal durability characteristics. Precision casting techniques, including low-pressure and flow-forming methods, create wheels with uniform material density and eliminated porosity defects. Computer-controlled machining operations achieve dimensional tolerances that ensure proper fitment and balanced operation throughout the wheel's service life. Quality assurance protocols including non-destructive testing identify potential defects before wheels enter service.

Heat treatment processes tailored to specific alloy compositions optimize material properties for durability and performance. Controlled cooling rates and temperature profiles create desired grain structures that maximize fatigue resistance and impact strength. Surface finishing operations including machining, polishing, and texturing prepare wheels for coating application while eliminating stress concentrations that could compromise long-term durability.

Rigorous testing protocols ensure that aluminum alloy wheels meet or exceed industry standards for durability and safety performance. Dynamic testing procedures simulate years of service conditions through accelerated fatigue testing, impact testing, and load cycling evaluations. Dimensional verification ensures proper fitment with tire and vehicle systems, preventing installation issues that could compromise performance or safety. Metallurgical analysis confirms alloy composition and material properties meet specified requirements.

Traceability systems track material sources, production parameters, and quality test results throughout the manufacturing process, enabling continuous improvement and rapid identification of potential issues. Statistical process control methods monitor production consistency and identify trends that could affect wheel quality or durability. These comprehensive quality systems ensure that each wheel meets stringent durability requirements before reaching end users.

The durability advantages of aluminum alloy wheels translate into reduced maintenance requirements and extended service intervals compared to conventional wheel materials. Corrosion resistance eliminates the need for frequent protective treatments or refinishing procedures, while structural integrity prevents the loosening or failure issues common with other materials. Cleaning procedures remain simple and effective due to smooth surface finishes and chemical resistance properties.

Inspection requirements focus on visual examination and basic dimensional checks rather than intensive structural assessments. The predictable wear patterns and failure modes of aluminum alloy wheels allow for straightforward condition monitoring without specialized equipment or procedures. This simplification of maintenance requirements reduces lifecycle costs while maintaining safety and performance standards.

The initial investment in aluminum alloy wheels typically provides favorable return through reduced operational costs and extended service life. Fuel economy improvements from weight reduction create ongoing savings that accumulate over the vehicle's operational period. Reduced maintenance requirements and extended component life throughout related vehicle systems contribute additional economic benefits beyond the immediate wheel performance advantages.

Resale value retention and market acceptance of vehicles equipped with aluminum alloy wheels provide additional economic incentives for their selection. The durability and appearance advantages translate into maintained vehicle value and enhanced marketability. These economic factors support the business case for aluminum alloy wheel selection across diverse vehicle applications and operational requirements.

Aluminum alloy wheels offer superior durability through their enhanced corrosion resistance, better heat dissipation, and optimized stress distribution characteristics. While steel wheels may appear more robust, aluminum alloys provide longer service life under typical automotive conditions due to their resistance to rust and environmental degradation. The reduced weight also decreases stress on suspension and drivetrain components, contributing to overall vehicle system durability.

Regular cleaning with appropriate automotive cleaners and periodic inspection for damage or wear represent the primary maintenance requirements for aluminum alloy wheels. Avoiding harsh chemicals or abrasive cleaning methods helps preserve protective coatings, while proper torque specifications during installation and rotation services ensure optimal performance. Professional refinishing may be required if coating damage occurs, but this is typically infrequent with proper care.

Many types of aluminum alloy wheel damage can be professionally repaired using specialized techniques including welding, machining, and refinishing procedures. Cosmetic damage such as curb rash or minor dents often responds well to repair services, while structural damage requires careful assessment to determine repair feasibility. Professional evaluation is essential to ensure that repaired wheels maintain their safety and durability characteristics.

Aluminum alloy wheels demonstrate excellent performance across diverse weather conditions due to their corrosion resistance and thermal properties. Cold weather applications benefit from reduced thermal shock sensitivity, while hot climate performance advantages include superior heat dissipation capabilities. The protective coating systems provide resistance to environmental challenges including salt exposure, temperature extremes, and moisture cycling that characterize severe weather conditions.

Hot News

Hot News