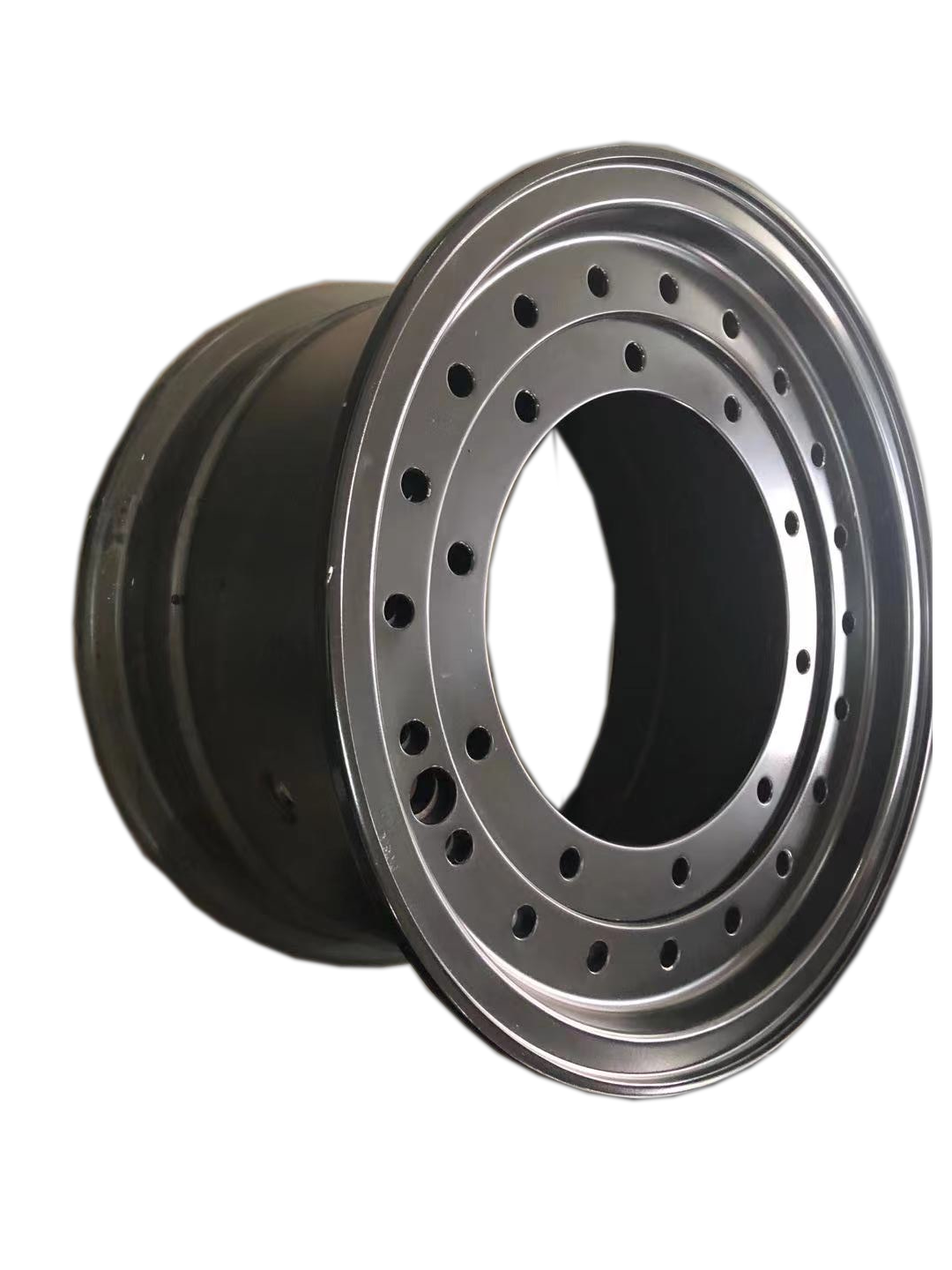

विभाजित पहियों की विश्वसनीयता

स्प्लिट पहियों की विश्वसनीयता आधुनिक पहिया निर्माण और सुरक्षा आकलन प्रोटोकॉल की एक महत्वपूर्ण बात है। यह व्यापक प्रणाली उद्योग, वाणिज्यिक और विशेष वाहन अनुप्रयोगों में आमतौर पर उपयोग किए जाने वाले स्प्लिट पहिया डिज़ाइनों की संरचनात्मक अखंडता, प्रदर्शन विश्वसनीयता और सुरक्षा मानकों का मूल्यांकन करती है। आकलन में कई परीक्षण चरण शामिल हैं, जिनमें सामग्री संरचना विश्लेषण, तनाव सहनशीलता मूल्यांकन और विभिन्न परिचालन स्थितियों में टिकाऊपन परीक्षण शामिल हैं। उन्नत कंप्यूटेशनल मॉडलिंग और वास्तविक दुनिया की परीक्षण प्रक्रियाएं मिलकर पहियों की सामान्य उपयोग और चरम परिस्थितियों के दौरान संरचनात्मक अखंडता बनाए रखने की क्षमता को सत्यापित करती हैं। प्रणाली विशेष रूप से पहिया घटकों के बीच महत्वपूर्ण जुड़ने वाले तंत्र पर ध्यान केंद्रित करती है, जिसमें लॉकिंग सिस्टम की विश्वसनीयता, बोल्ट तनाव और सीलिंग प्रभावकारिता का विश्लेषण किया जाता है। आधुनिक स्प्लिट पहियों की विश्वसनीयता आकलन में डिजिटल निगरानी प्रणाली शामिल हैं, जो पहियों के जीवनकाल में घिसाव, तनाव वितरण और संभावित विफलता के बिंदुओं की निगरानी करती हैं। डेटा आधारित इस दृष्टिकोण से निर्माताओं और सुरक्षा नियामकों को व्यापक विश्वसनीयता मापदंड स्थापित करने और रखरखाव आवश्यकताओं की सटीक भविष्यवाणी करने में सक्षम बनाता है। विश्वसनीयता मूल्यांकन पर्यावरणीय कारकों पर भी विचार करता है, जैसे तापमान में परिवर्तन, नमी के संपर्क में आना और रासायनिक प्रतिरोध, यह सुनिश्चित करना कि पहिये विविध परिचालन वातावरण में अपनी अखंडता बनाए रखते हैं।

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

AF

AF

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MN

MN

SO

SO

MY

MY

KK

KK

UZ

UZ

KU

KU

KY

KY