laser antidrone defense system factory

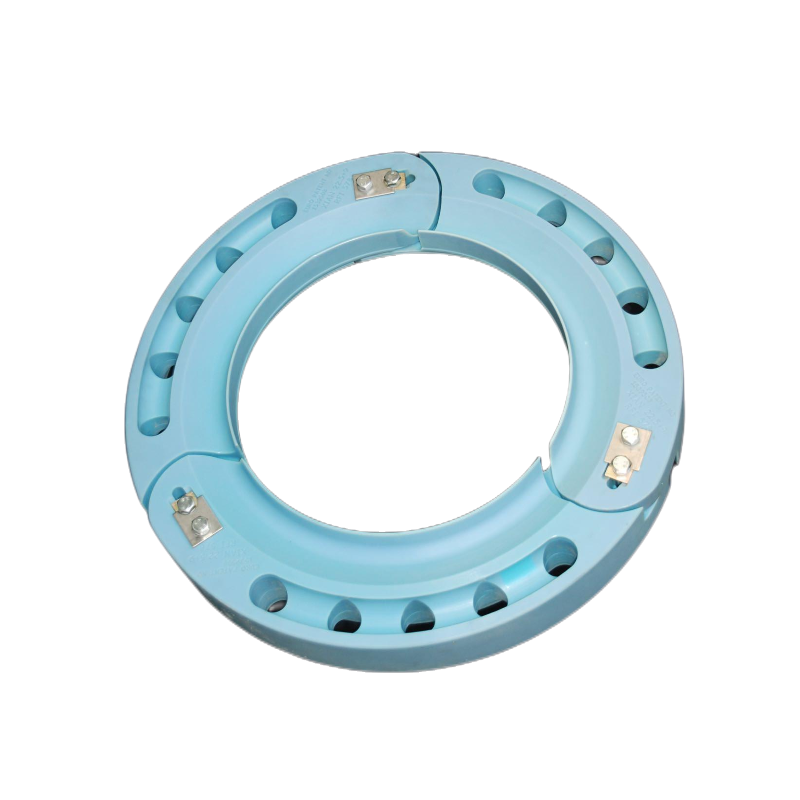

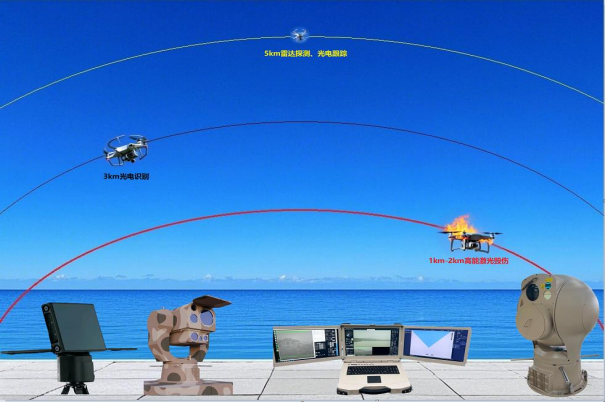

The laser antidrone defense system factory represents a cutting-edge manufacturing facility dedicated to producing advanced counter-UAV solutions. This state-of-the-art facility integrates precision engineering, advanced optics manufacturing, and sophisticated electronic systems assembly to create highly effective drone defense systems. The factory employs multiple production lines equipped with automated quality control systems, ensuring consistent output of high-performance laser systems capable of detecting, tracking, and neutralizing unauthorized drones. The facility's clean room environments maintain strict environmental controls for the assembly of sensitive optical components, while specialized testing chambers verify the functionality of each system under various atmospheric conditions. The factory incorporates modern robotics for handling delicate components and implements rigorous calibration procedures to maintain precise alignment of laser systems. Research and development laboratories within the facility continuously work on improving system efficiency, developing new targeting algorithms, and enhancing the overall effectiveness of anti-drone capabilities. The facility also houses advanced simulation environments for testing system responses to various drone threats, ensuring reliable performance in real-world scenarios. With comprehensive quality management systems in place, the factory maintains international safety standards and compliance with regulatory requirements for laser system manufacturing.

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

AF

AF

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MN

MN

SO

SO

MY

MY

KK

KK

UZ

UZ

KU

KU

KY

KY