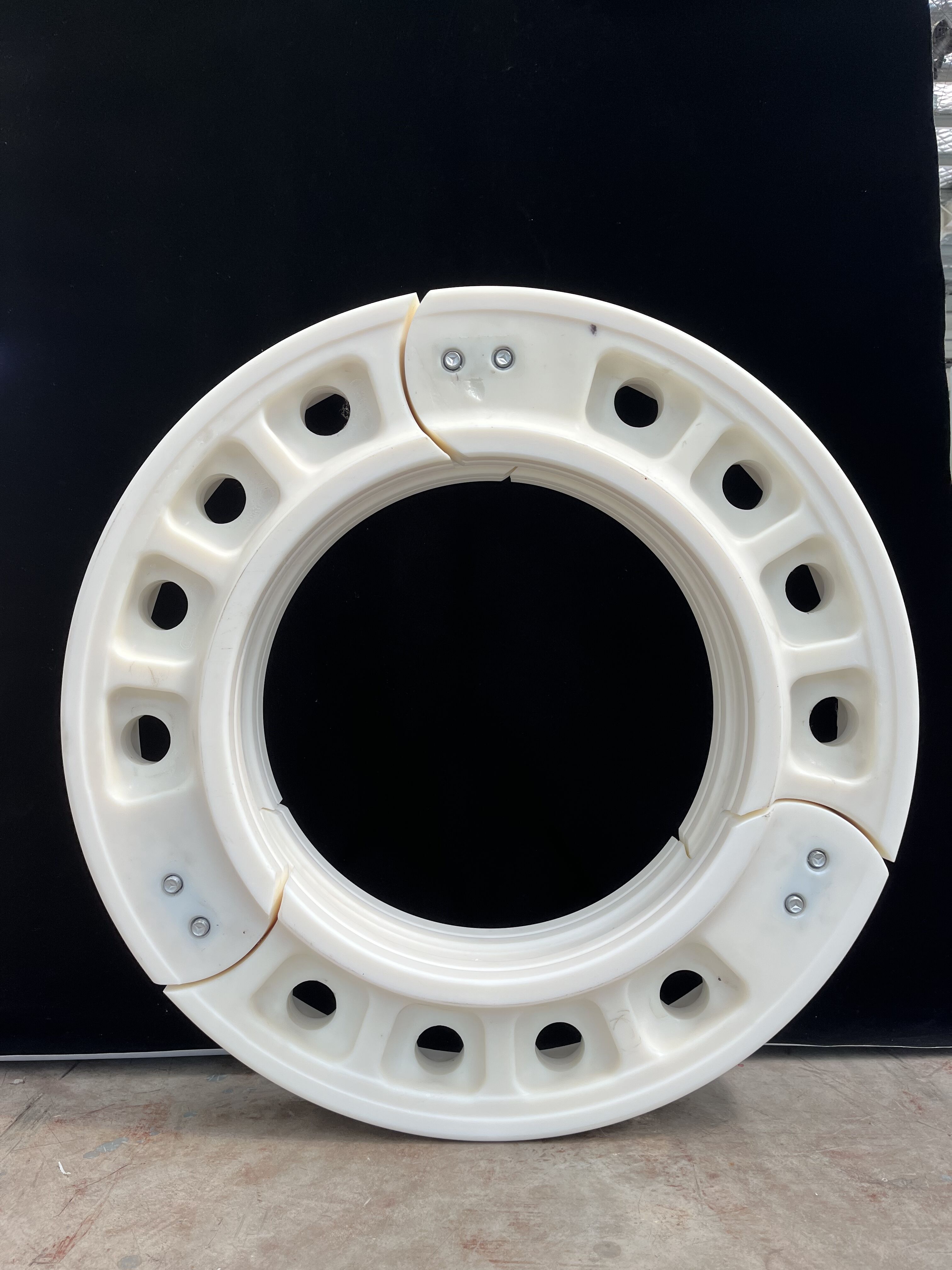

split wheel

A split wheel is an innovative engineering solution designed to provide enhanced versatility and functionality in various industrial applications. This specialized wheel design features a unique construction where the wheel is divided into two or more segments that can be assembled or disassembled as needed. The split wheel configuration allows for easier installation, maintenance, and replacement, particularly in confined spaces or areas with limited access. The design typically incorporates precision-engineered components that ensure proper alignment and balanced weight distribution when assembled. Split wheels are manufactured using high-grade materials that offer excellent durability and load-bearing capabilities. They often feature specialized coating or treatment processes to enhance their resistance to wear, corrosion, and environmental factors. The technology behind split wheels has evolved to include advanced locking mechanisms that ensure secure assembly while maintaining optimal performance under various operating conditions. These wheels find extensive applications in material handling equipment, industrial machinery, construction equipment, and specialized vehicles where traditional solid wheels might pose installation or maintenance challenges. The versatility of split wheels makes them particularly valuable in scenarios requiring frequent wheel changes or maintenance in hard-to-reach areas, significantly reducing equipment downtime and maintenance costs.

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

AF

AF

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MN

MN

SO

SO

MY

MY

KK

KK

UZ

UZ

KU

KU

KY

KY