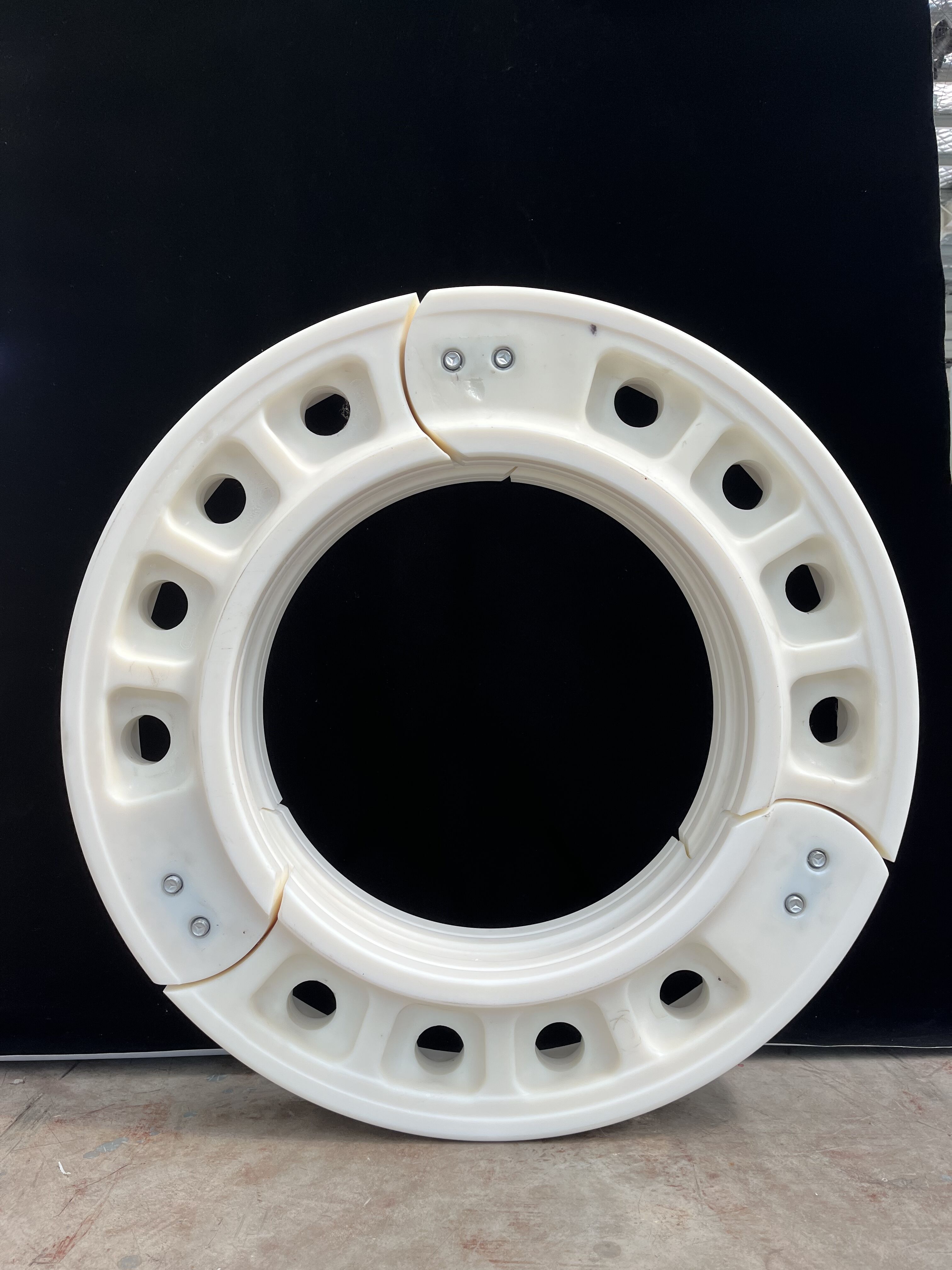

split hjul

En delad hjul är en innovativ ingenjörsösning som är utformad för att erbjuda ökad mångsidighet och funktionalitet i olika industriella applikationer. Detta specialdesignade hjul har en unik konstruktion där hjulet är uppdelat i två eller flera segment som kan monteras eller demonteras efter behov. Den delade hjulkonfigurationen möjliggör enklare installation, underhåll och utbyte, särskilt i trånga utrymmen eller områden med begränsad tillgång. Konstruktionen inkluderar vanligtvis precisionsutformade komponenter som säkerställer korrekt justering och balanserad viktfördelning vid montering. Delade hjul tillverkas med material av hög kvalitet som erbjuder utmärkt hållbarhet och bärförmåga. De är ofta försedda med särskilda beläggningar eller behandlingsprocesser för att förbättra deras motståndskraft mot slitage, korrosion och miljöpåverkan. Tekniken bakom delade hjul har utvecklats för att inkludera avancerade låsmekanismer som säkerställer säker montering samtidigt som optimal prestanda upprätthålls under olika driftsförhållanden. Dessa hjul används omfattande i materialhanteringsutrustning, industriella maskiner, byggnadsutrustning och specialfordon där traditionella solidhjul kan innebära installations- eller underhållsproblem. Mångsidigheten hos delade hjul gör dem särskilt värdefulla i situationer som kräver frekventa hjulbyten eller underhåll i svåråtkomliga områden, vilket minskar driftstopp och underhållskostnader avsevärt.