Intelligent Monitoring System

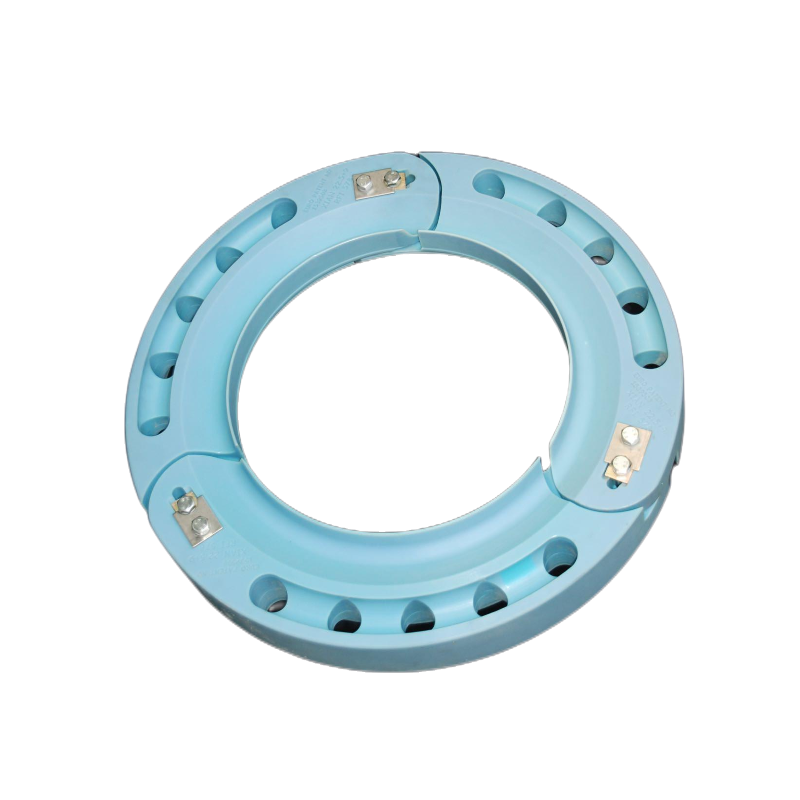

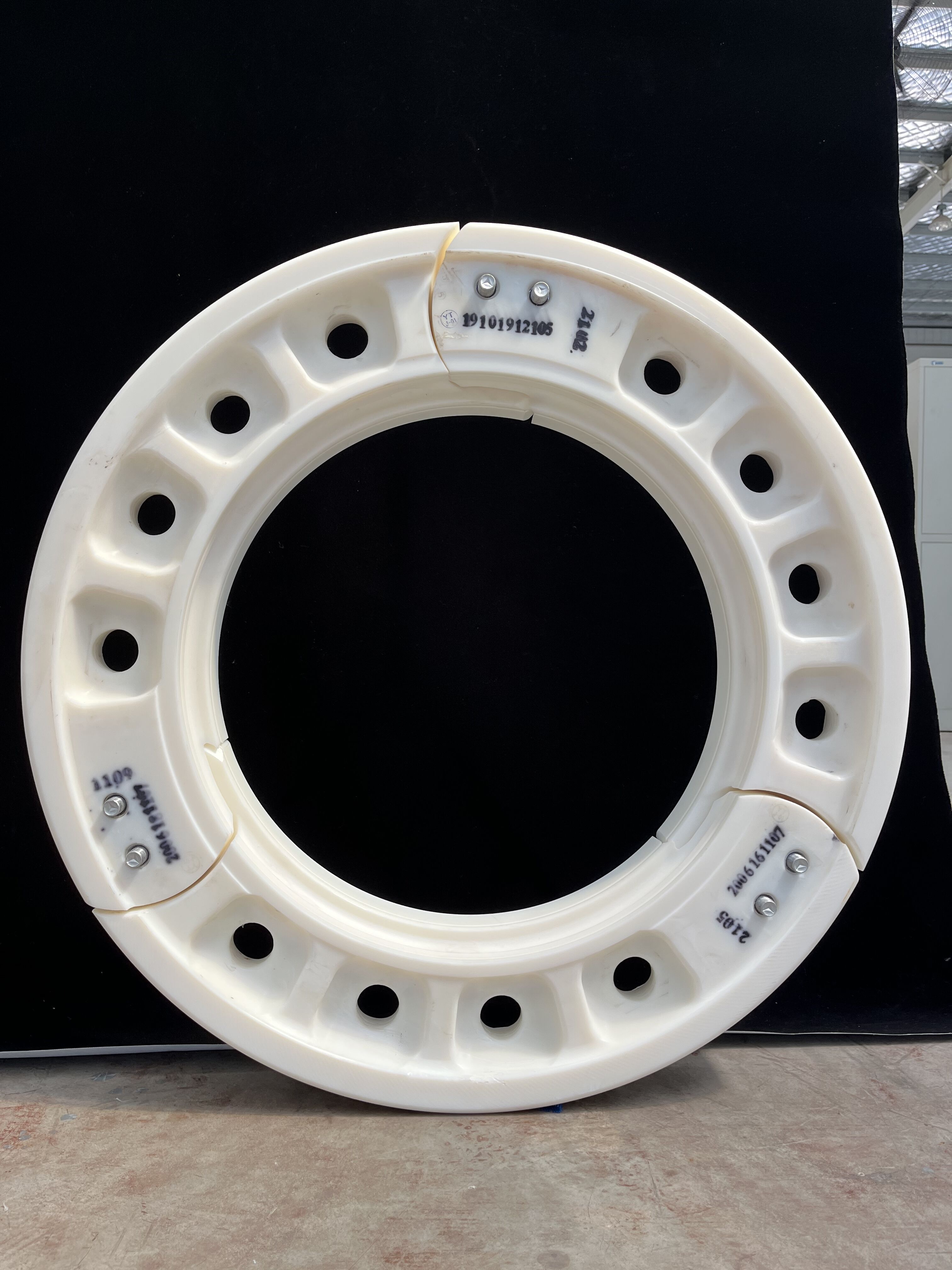

A sophisticated monitoring system is integrated into the split wheels design, providing continuous real-time data on various performance parameters. This intelligent system utilizes advanced sensors and analytics to track wheel alignment, temperature, pressure, and wear patterns. The monitoring capabilities enable predictive maintenance scheduling, helping to prevent unexpected failures and optimize maintenance intervals. The system also includes alert mechanisms that notify operators of potential issues before they become critical, ensuring maximum uptime and operational efficiency.

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

AF

AF

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MN

MN

SO

SO

MY

MY

KK

KK

UZ

UZ

KU

KU

KY

KY