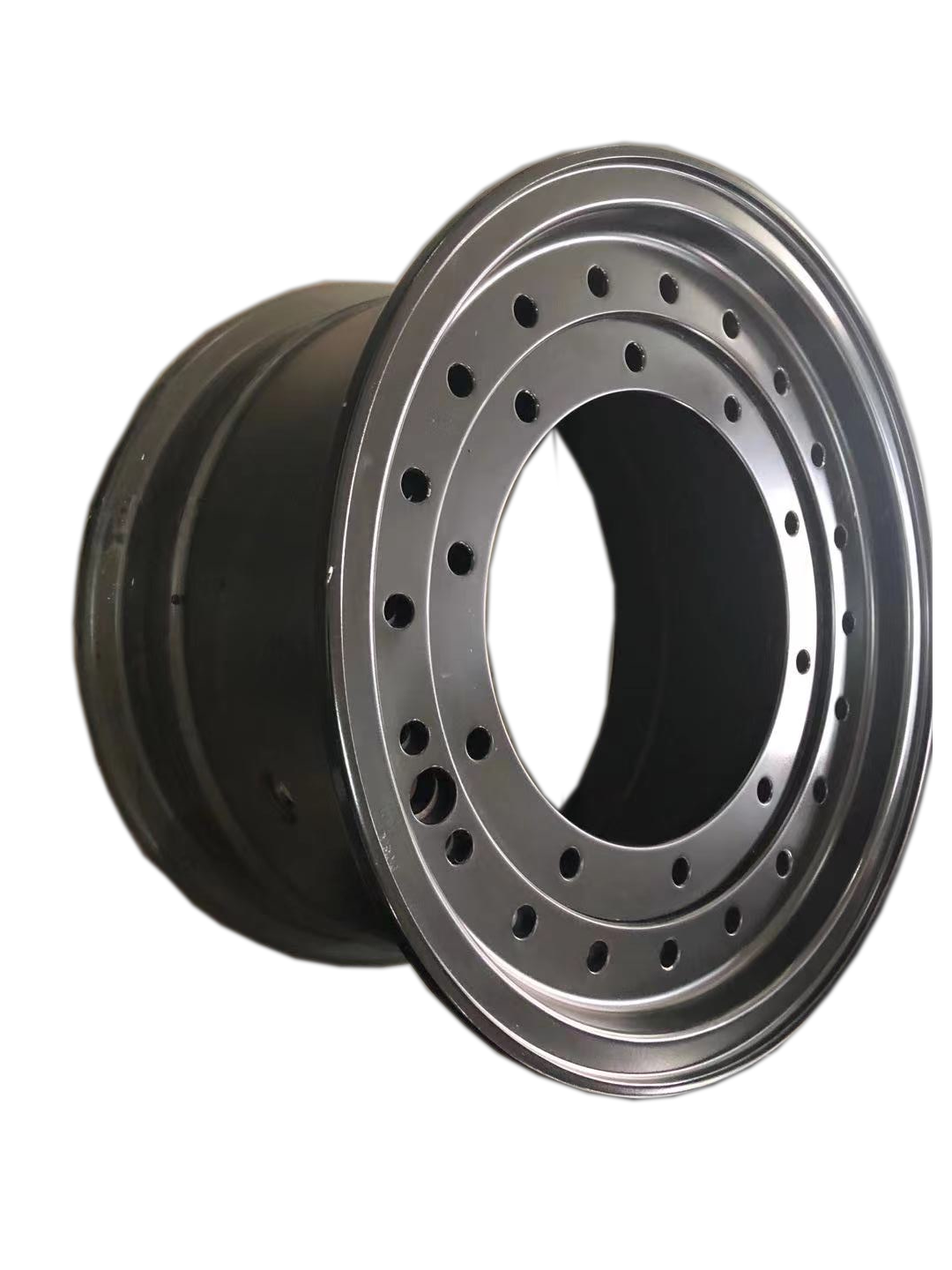

oem alloy wheels

OEM alloy wheels represent the pinnacle of automotive wheel manufacturing, combining precision engineering with superior design aesthetics. These wheels are specifically manufactured to meet the exact specifications set by original equipment manufacturers, ensuring perfect fitment and optimal performance for specific vehicle models. Crafted from high-grade aluminum alloys, these wheels offer an impressive strength-to-weight ratio that contributes to enhanced vehicle performance and fuel efficiency. The manufacturing process involves advanced casting techniques, heat treatment, and rigorous quality control measures to ensure structural integrity and longevity. OEM alloy wheels are designed to complement the vehicle's suspension geometry and brake system, maintaining the original handling characteristics while potentially improving overall performance. They feature precise bolt patterns, offset measurements, and load ratings that match the vehicle's original specifications, ensuring safety and reliability. The wheels undergo extensive testing for impact resistance, fatigue strength, and environmental durability, meeting or exceeding international safety standards. Additionally, these wheels often incorporate sophisticated design elements that enhance both aesthetics and aerodynamic efficiency, contributing to the vehicle's overall performance and visual appeal.

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

AF

AF

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MN

MN

SO

SO

MY

MY

KK

KK

UZ

UZ

KU

KU

KY

KY