support body solutions for vehicle manufacturers

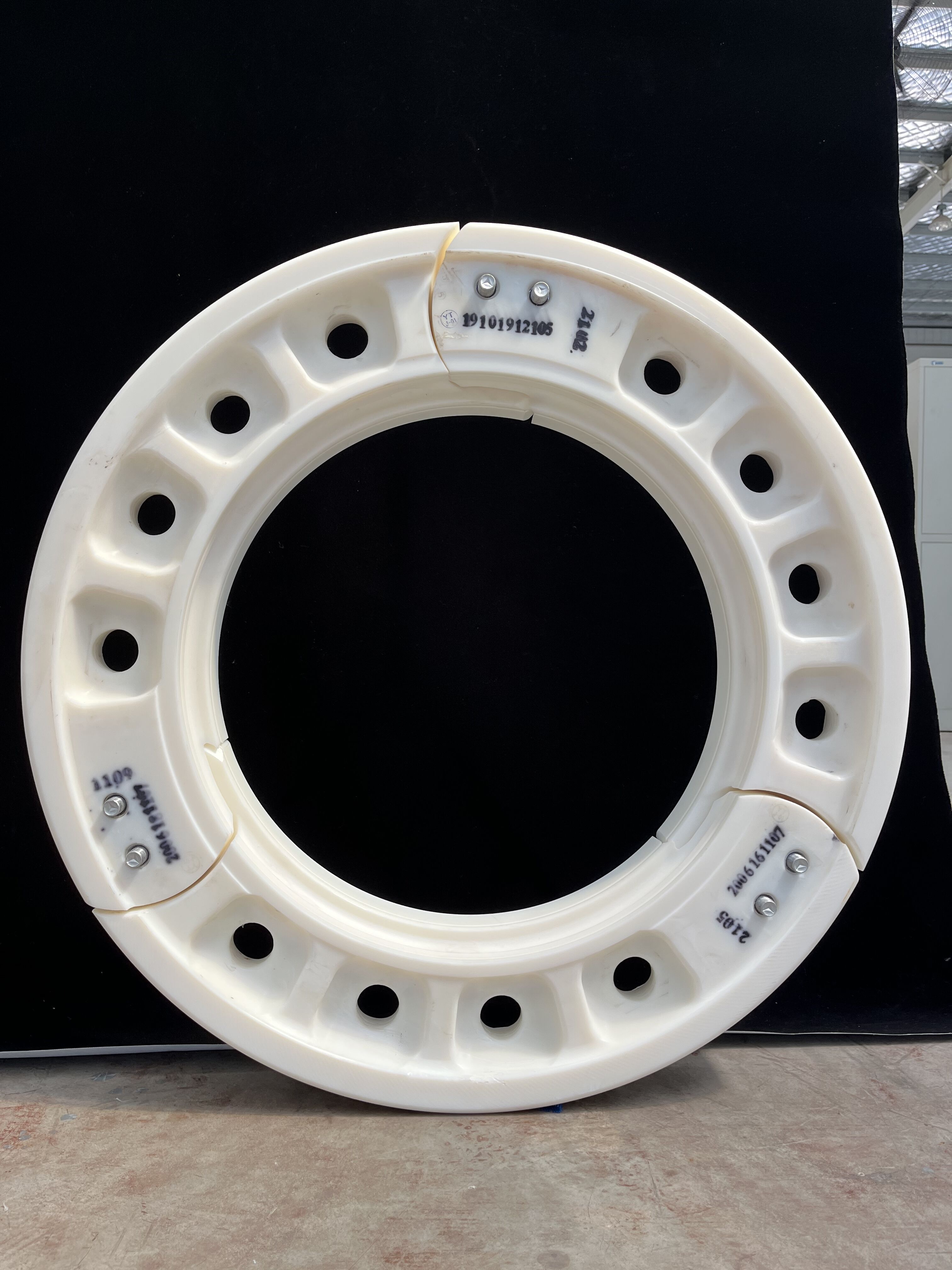

Support body solutions for vehicle manufacturers represent a comprehensive system designed to enhance the production, assembly, and quality control processes in automotive manufacturing. These solutions encompass advanced structural frameworks, modular components, and innovative assembly systems that form the backbone of modern vehicle production. The technology integrates sophisticated computer-aided design (CAD) systems with precision engineering to create adaptable manufacturing platforms that can accommodate various vehicle models and specifications. These solutions incorporate smart manufacturing principles, utilizing sensors and automated systems to ensure precise alignment, optimal weight distribution, and structural integrity throughout the production process. The systems are designed to meet stringent safety standards while maintaining production efficiency and scalability. They feature advanced materials that combine lightweight properties with exceptional strength, contributing to improved fuel efficiency and vehicle performance. The solutions also include integrated quality control mechanisms that monitor assembly accuracy and structural integrity in real-time. Furthermore, these systems are designed with sustainability in mind, incorporating recyclable materials and energy-efficient processes that align with modern environmental standards. The support body solutions are particularly valuable in their ability to adapt to changing market demands and new vehicle designs, offering manufacturers the flexibility to modify production lines quickly and efficiently.

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

AF

AF

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MN

MN

SO

SO

MY

MY

KK

KK

UZ

UZ

KU

KU

KY

KY