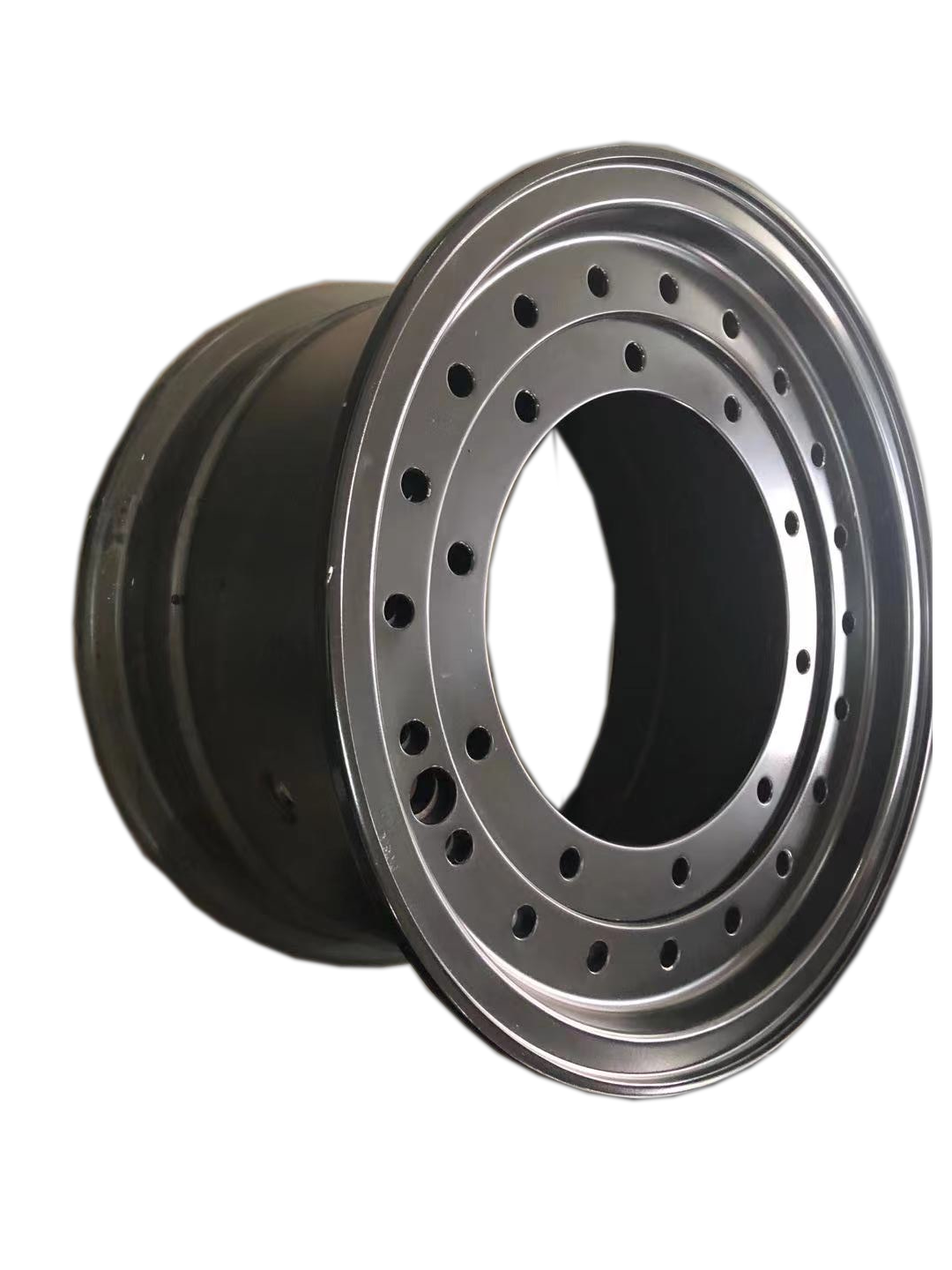

split wheels trustworthiness

Split wheels trustworthiness represents a crucial aspect of modern wheel manufacturing and safety assessment protocols. This comprehensive system evaluates the structural integrity, performance reliability, and safety standards of split wheel designs commonly used in industrial, commercial, and specialized vehicle applications. The assessment encompasses multiple testing phases, including material composition analysis, stress tolerance evaluation, and durability testing under various operational conditions. Advanced computational modeling and real-world testing procedures work together to verify the wheel's ability to maintain structural integrity during normal usage and extreme conditions. The system particularly focuses on the critical joining mechanisms between wheel components, analyzing the reliability of locking systems, bolt tensions, and sealing effectiveness. Modern split wheel trustworthiness assessment incorporates digital monitoring systems that track wear patterns, stress distribution, and potential failure points throughout the wheel's lifecycle. This data-driven approach enables manufacturers and safety regulators to establish comprehensive reliability metrics and predict maintenance requirements accurately. The trustworthiness evaluation also considers environmental factors, such as temperature variations, moisture exposure, and chemical resistance, ensuring the wheels maintain their integrity across diverse operating environments.

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

AF

AF

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MN

MN

SO

SO

MY

MY

KK

KK

UZ

UZ

KU

KU

KY

KY