fixing aluminum rims

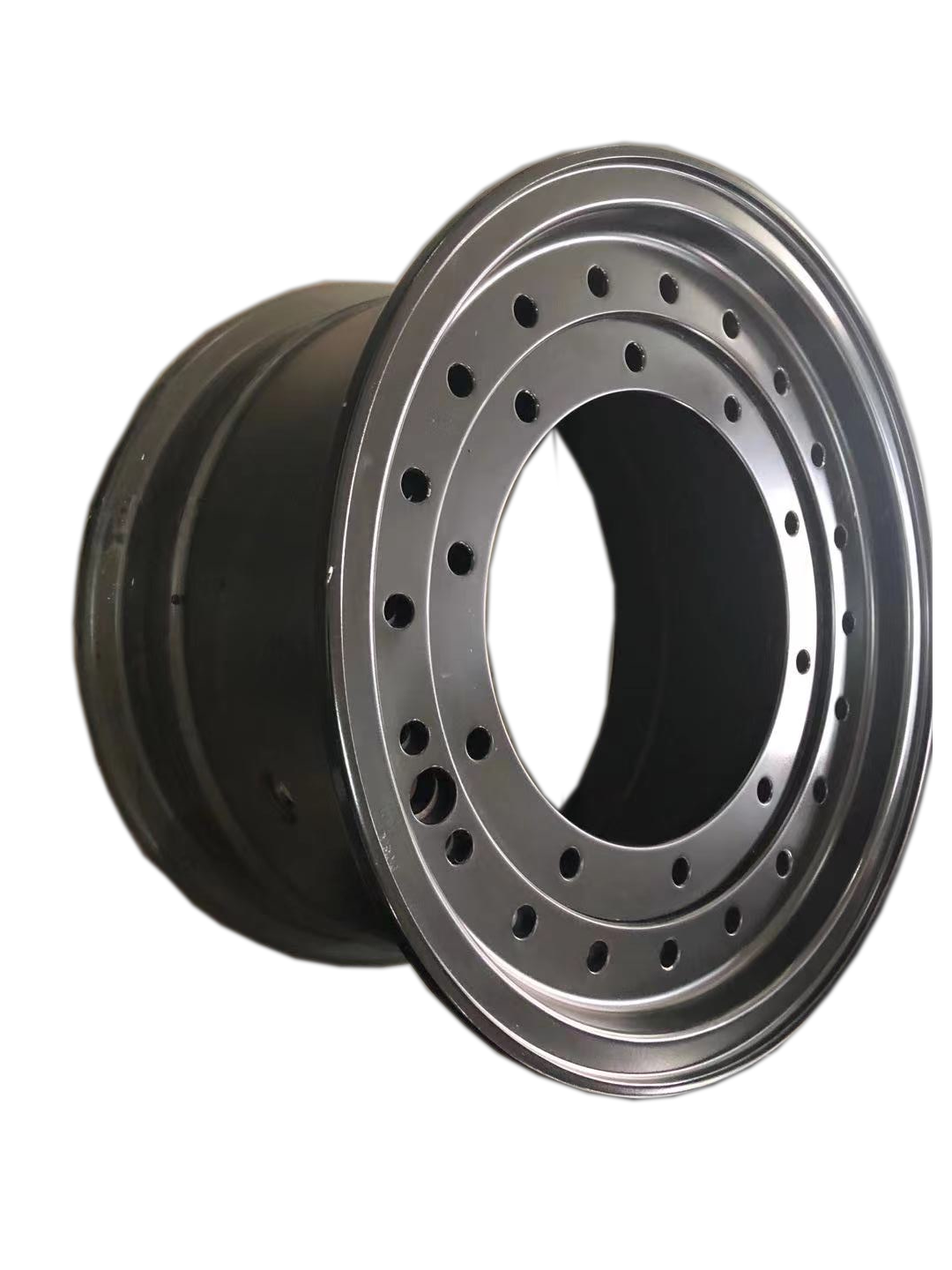

Fixing aluminum rims is a critical process that involves restoring damaged or compromised wheel rims to their original condition and structural integrity. This comprehensive repair process encompasses various techniques, including straightening bent sections, filling cracks, and refinishing surfaces to match factory specifications. Modern aluminum rim repair utilizes advanced technologies such as computerized wheel straightening machines, specialized welding equipment, and high-grade aluminum fillers. The process begins with a thorough inspection to assess damage extent, followed by precision straightening using hydraulic pressure systems. Specialized technicians employ TIG welding for crack repairs, ensuring the molecular structure of the aluminum remains intact. The repair process also includes chemical cleaning, surface preparation, and the application of protective coatings to prevent future corrosion. This service is particularly valuable for luxury and performance vehicles where replacement costs are substantial. The technology has evolved to address various types of damage, from minor cosmetic issues to significant structural problems, making it possible to restore rims to both their aesthetic appeal and safety standards.

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

AF

AF

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MN

MN

SO

SO

MY

MY

KK

KK

UZ

UZ

KU

KU

KY

KY