aluminum alloy rims

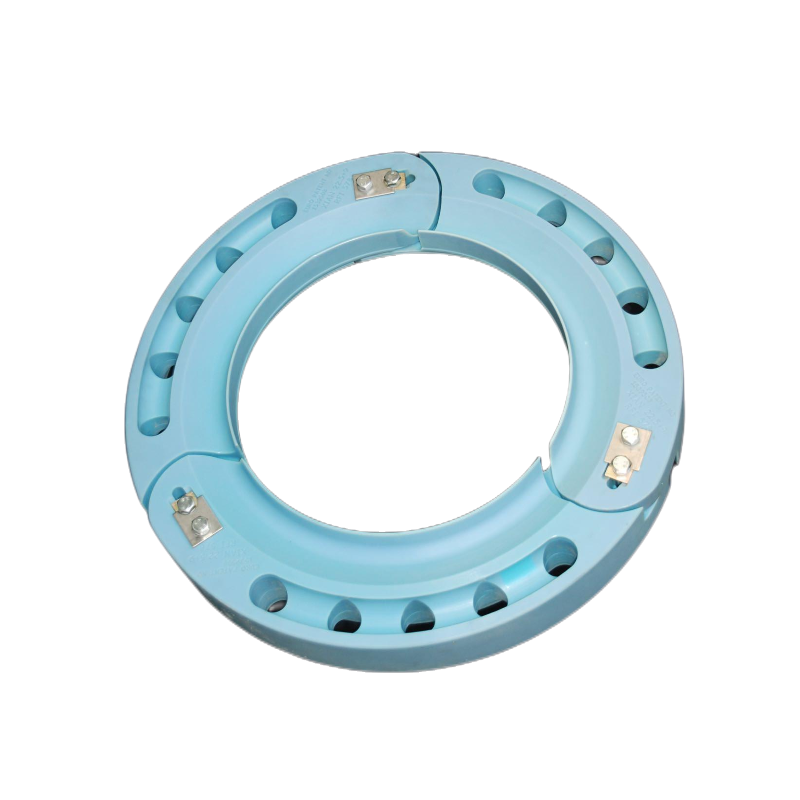

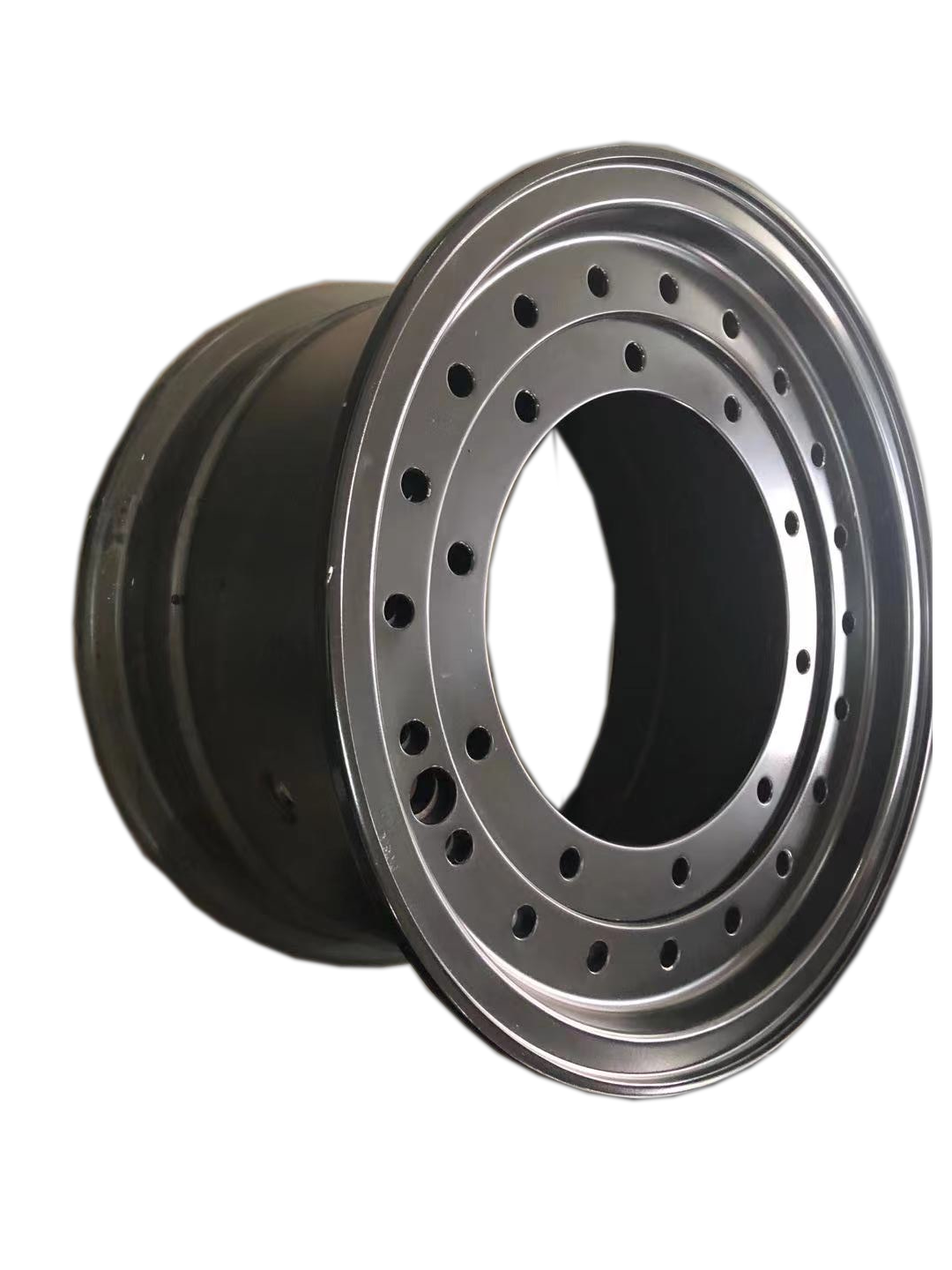

Aluminum alloy rims represent a pinnacle of automotive engineering, combining lightweight durability with sophisticated design aesthetics. These advanced wheel components are manufactured through a precise casting or forging process, utilizing high-grade aluminum alloys that offer an optimal balance of strength and weight reduction. The rims typically feature a specialized construction that incorporates various elements, including spokes, the outer lip, and the hub mounting surface, all precisely engineered to ensure maximum structural integrity. Modern aluminum alloy rims often incorporate advanced surface treatments and protective coatings that enhance both durability and appearance, making them resistant to corrosion and environmental damage. These rims serve multiple crucial functions in vehicle performance, including heat dissipation during braking, reduction of unsprung weight for improved handling, and enhancement of overall vehicle aesthetics. The manufacturing process employs cutting-edge technology, including computer-aided design and precision machining, to create rims that meet strict safety standards while delivering optimal performance characteristics. They are widely used across various vehicle types, from everyday passenger cars to high-performance sports vehicles, offering versatility in both function and design.

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

AF

AF

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MN

MN

SO

SO

MY

MY

KK

KK

UZ

UZ

KU

KU

KY

KY